COMPRESSED AIR CONDITIONING

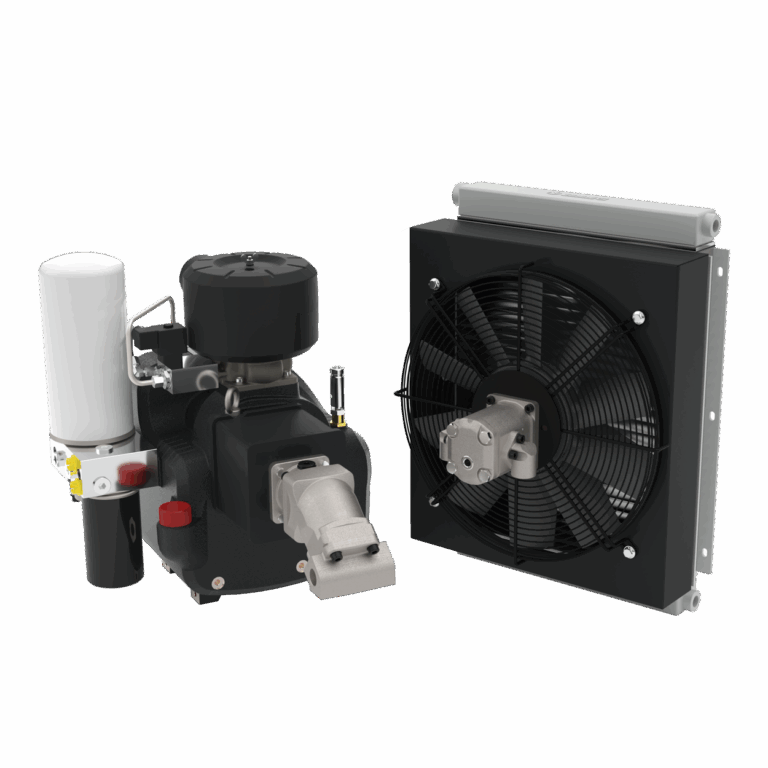

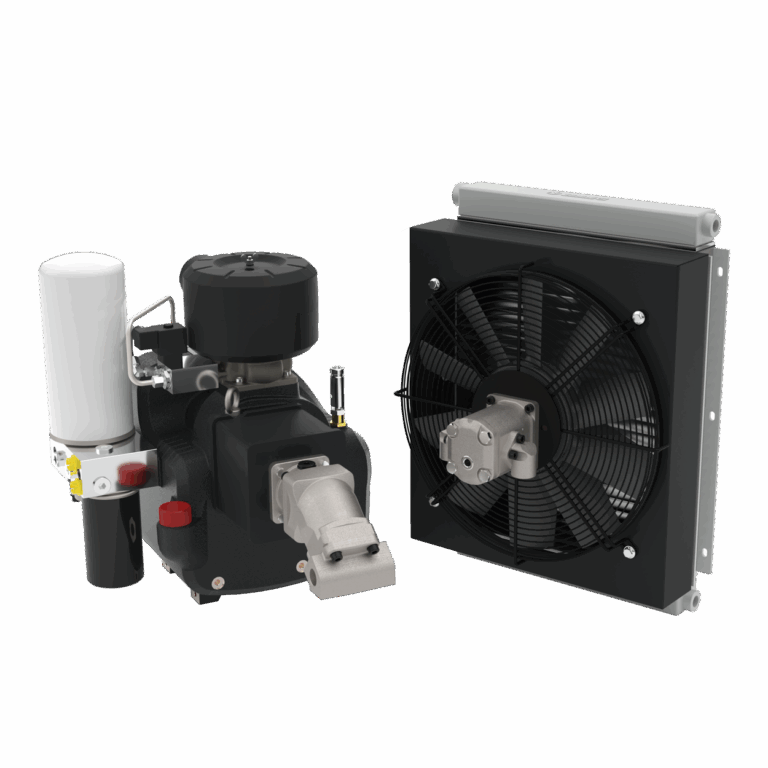

To inflate the tyres quickly and minimise downtime in the field, a high-capacity compressed air compressor is recommended. For air production, vane compressors and screw compressors are most commonly used.

To prevent oil quality from deteriorating due to short compressor cycles – which could impair compressor performance – we have integrated a function into the QTIS software that helps maintain optimal oil condition.

Generate en dry compressed air

To inflate the tyres quickly and minimise downtime in the field, a high-capacity compressed air compressor is recommended. For air production, vane compressors and screw compressors are most commonly used.

To prevent oil quality from deteriorating due to short compressor cycles – which could impair compressor performance – we have integrated a function into the QTIS software that helps maintain optimal oil condition.