QTIS BANDENDRUKREGELSYSTEEM

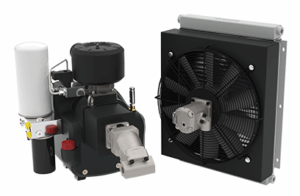

Persluchtconditionering

Vultijden van uw banden worden door uw compressorcapaciteit bepaald, perslucht droging voorkomt stilstand.

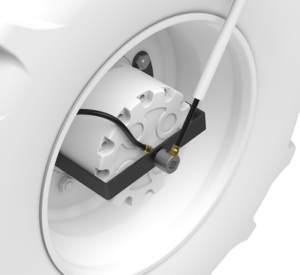

Draaidoorvoeren voor over het spatbord montage

QTIS draaidoorvoeren voor tractors en trailers, corrosie-bestendig en jarenlange standtijden.

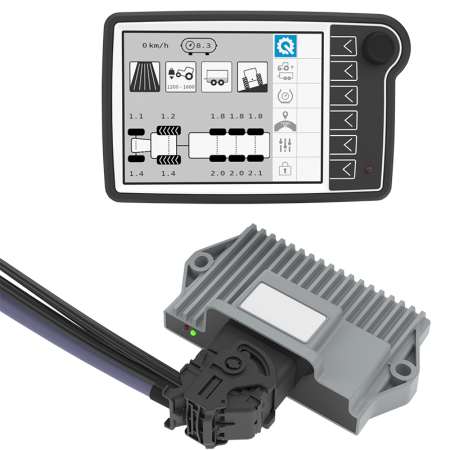

Elektronische besturing

QTIS biedt twee modellen ECU’ s passend bij uw bekabelings-systeem. CAN, ISOBUS, AEF en zeer betaalbaar geprijsd.

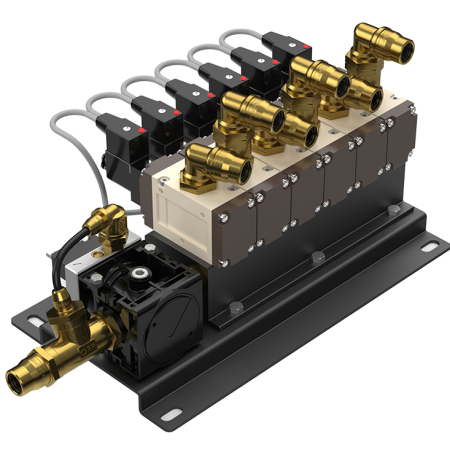

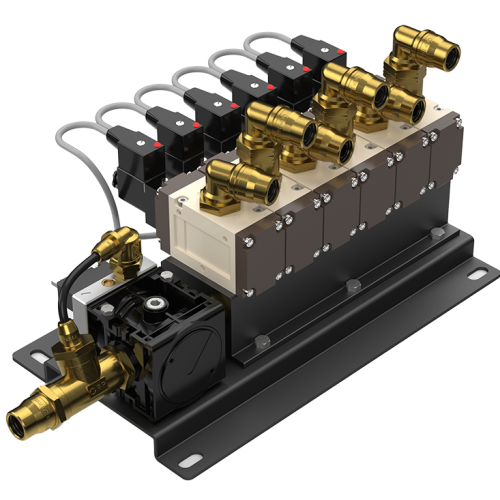

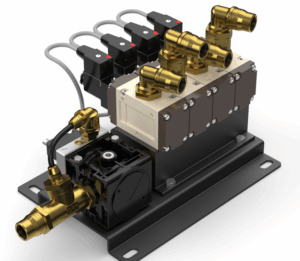

Ventieleiland

Het compacte QTIS 4 of 6-voudige ventieleiland om uw banden te vullen en ontluchten met één enkele leiding.

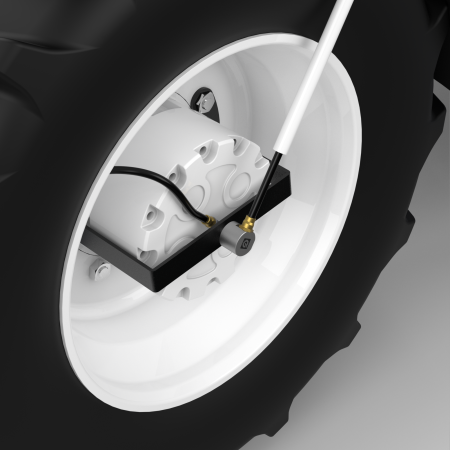

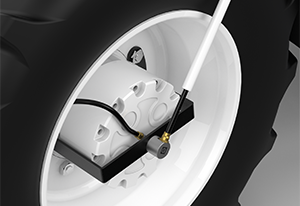

Wielventiel

Zeer snelle ontluchting, gefilterde bandenlucht direct naar buiten. Slechts één leiding met grote doorlaat voor alle functies.

Toebehoren

Kabelsets, fittingen, filters, slangen, tanks of water-afscheiders. De service-producten waar u vast mee bekend bent.

Draaidoorvoeren door de geboorde as

QTIS draaidoorvoeren voor trailers, corrosiebestendig en jarenlange standtijden.

TPMS

Draadloze bandendruk-sensoren om de juiste bandendrukken snel te kunnen meten, presenteren, en aanpassen.

QTIS BANDENDRUKREGELSYSTEEM

Waarom een bandendrukregelsysteem?

Bandenvervanging en brandstof zijn twee forse kostenposten in uw agrarische bedrijfsvoering. Dus u heeft al uw land nodig om met goede opbrengsten deze kosten te dekken. Een bandendrukregelsysteem (CTIS, Central Tyre Inflation System) zorgt voor kostenbesparingen, verhoogde veiligheid en verhoogde productiviteit. Door de klimaatverandering is de kans op lange natte periodes sterk toegenomen. Het QTIS® bandendruk regelsysteem zal u helpen eerder en langer in het veld te werken. Feitelijk betaalt het system zichzelf terug. Betrouwbaar, slim en betaalbaar!

- Minder banden slijtage, meer effectieve velduren

- Langer veldseizoen, minder stilstand en uitval

- Minder bodemverdichting, hogere opbrengsten

- Meer grip, meer effectieve trekkracht

- Lager brandstofgebruik, in het veld en op de weg

- Snelle wisseling van de bandenspanning, minder wachttijden

- Betere voertuigbeheersing , wegligging en remgedrag

Waarom een QTIS bandendrukregelsysteem?

We zijn niet over één nacht ijs gegaan bij de herontwikkeling van ons QTIS bandendrukregelsysteem. De ontwerpeisen zijn opgesteld uit onze jarenlange ervaring, overleg met onze klanten én met gebruikers van andere merken in de markt. Op deze wijze hebben we onszelf uitgedaagd door alle gevraagde verbeteringen mee te nemen in een herontwerp. We hebben volgende ontwerpeisen inmiddels voor u gerealiseerd:

- Geschikt voor Tractoren, zelfrijders en trailers, met bandendrukken tot 6,5bar en tot 1800 l/min FAD vulsnelheid per band. (compressor afhankelijk).

- Modulaire opbouw, kies de componenten die u wenst en gebuik eigen kennis en componenten waar u wenst.

- ISOBUS besturing met eenvoudige instelling van bandendrukken bij wisselende ondergrond, belading en terreinhelling.

- Eén leiding voor banden vullen en legen, die drukloos is als de banden op de juiste spanning zijn.

- Geen risico op schade in het geval van aflopende slangen.

- Geen vuile bandenlucht terug in het schone perslucht systeem. Bandenlucht wordt bij het afblazen gefilterd en direct naar buiten afgeblazen.

- Correcte drukmeting in de band om zo drukverschillen van stromende lucht in de toevoerleiding ten opzichte van de bandendruk te voorkomen.

- Grote doorlaten voor de beste ontluchttijden in de markt, en voor een maximale benutting van de compressor capaciteit bij het verhogen van de bandendruk.

- Waarschuwing voor onder andere lekkages, banden oververhitting, compressor management.

- Robuuste en corrosiebestendige materialen en producten, demonteerbaar, reinigbaar, repareerbaar.

- Eenvoudige en snelle montage, geschikt voor seriematige inbouw.

- Lage prijs niveaus geschikt voor OEM seriematige inbouw.

Waarom een bandendrukregelsysteem?

Bandenvervanging en brandstof zijn twee forse kostenposten in uw agrarische bedrijfsvoering. Dus u heeft al uw land nodig om met goede opbrengsten deze kosten te dekken. Een bandendrukregelsysteem (CTIS, Central Tyre Inflation System) zorgt voor kostenbesparingen, verhoogde veiligheid en verhoogde productiviteit. Door de klimaatverandering is de kans op lange natte periodes sterk toegenomen. Het QTIS® bandendruk regelsysteem zal u helpen eerder en langer in het veld te werken. Feitelijk betaalt het system zichzelf terug. Betrouwbaar, slim en betaalbaar!

- Minder banden slijtage, meer effectieve velduren

- Langer veldseizoen, minder stilstand en uitval

- Minder bodemverdichting, hogere opbrengsten

- Meer grip, meer effectieve trekkracht

- Lager brandstofgebruik, in het veld en op de weg

- Snelle wisseling van de bandenspanning, minder wachttijden

- Betere voertuigbeheersing , wegligging en remgedrag

Waarom een QTIS bandendrukregelsysteem?

We zijn niet over één nacht ijs gegaan bij de herontwikkeling van ons QTIS bandendrukregelsysteem. De ontwerpeisen zijn opgesteld uit onze jarenlange ervaring, overleg met onze klanten én met gebruikers van andere merken in de markt. Op deze wijze hebben we onszelf uitgedaagd door alle gevraagde verbeteringen mee te nemen in een herontwerp. We hebben volgende ontwerpeisen inmiddels voor u gerealiseerd:

- Geschikt voor Tractoren, zelfrijders en trailers, met bandendrukken tot 6,5bar en tot 1800 l/min FAD vulsnelheid per band. (compressor afhankelijk).

- Modulaire opbouw, kies de componenten die u wenst en gebuik eigen kennis en componenten waar u wenst.

- ISOBUS besturing met eenvoudige instelling van bandendrukken bij wisselende ondergrond, belading en terreinhelling.

- Eén leiding voor banden vullen en legen, die drukloos is als de banden op de juiste spanning zijn.

- Geen risico op schade in het geval van aflopende slangen.

- Geen vuile bandenlucht terug in het schone perslucht systeem. Bandenlucht wordt bij het afblazen gefilterd en direct naar buiten afgeblazen.

- Correcte drukmeting in de band om zo drukverschillen van stromende lucht in de toevoerleiding ten opzichte van de bandendruk te voorkomen.

- Grote doorlaten voor de beste ontluchttijden in de markt, en voor een maximale benutting van de compressor capaciteit bij het verhogen van de bandendruk.

- Waarschuwing voor onder andere lekkages, banden oververhitting, compressor management.

- Robuuste en corrosiebestendige materialen en producten, demonteerbaar, reinigbaar, repareerbaar.

- Eenvoudige en snelle montage, geschikt voor seriematige inbouw.

- Lage prijs niveaus geschikt voor OEM seriematige inbouw.